Implement effective risk-management strategies and systems based on sound science, and which account for stakeholder perceptions of risk.

Materials Stewardship

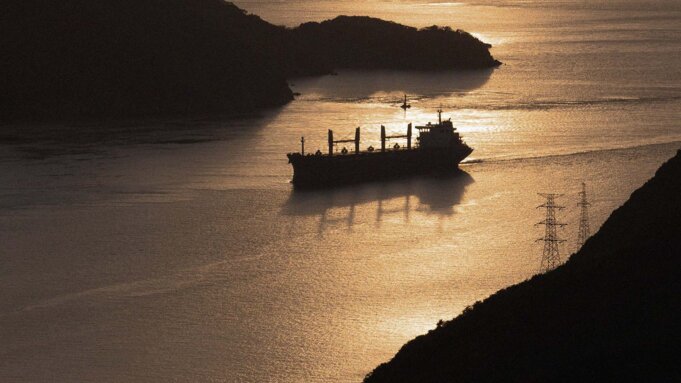

The energy transition is materials intensive, requiring more metals and minerals to be used, handled, and transported safely across the globe.

Complex materials like minerals, ores, concentrates, and metals present unique challenges. ICMM’s commitment to a safe, fair, and sustainable mining and metals industry goes beyond resource extraction – it extends to every stage of materials stewardship. In collaboration with commodity and country associations, we are ensuring that mining and metals products uphold the highest environmental and safety standards, comply with evolving regulations, and promote circularity.

Issue at a glance

- Metals and minerals are essential to almost all aspects of life; they enable farming, healthcare, communications, water and energy supply, transport, and the sustainable construction of our cities.

- Materials stewardship is built on the premise that the mining and metals industry has a shared responsibility for the performance of the whole materials cycle, well beyond direct operations.

- Materials stewardship includes both process and product elements. Process stewardship focuses on minimising environmental impacts and health and safety risks during exploration, extraction, and refining. Product stewardship addresses the use of minerals, metals, and inorganic metal compounds in products, guiding their application to reduce risks and encourage recovery, reuse, or recycling where appropriate.

- Metals are the ideal durable material. Growing demand for minerals, driven by clean energy technologies and population growth, necessitates embracing circularity principles to enhance material productivity, eliminate waste, and regenerate nature.

Assessing product hazards

Metals and minerals only pose a hazard under certain conditions, known as the route of exposure. For instance, solder fumes are highly toxic when inhaled but safe if they encounter skin. A chemical’s hazard classification is based on its inherent hazards, not normal usage conditions, where exposure is unlikely to cause harm. The industry has long argued that this gap needs addressing. How metals and minerals are classified directly impacts their use, as classification forms the foundation for other regulatory controls.

Hazard classification has several critical implications across various sectors:

- Transportation: Determines how hazardous materials can be safely transported, influencing packaging requirements and transport mode regulations.

- Worker health and safety: Triggers necessary health protection measures, such as air extraction and respiratory protection, for workers exposed to inhalation hazards.

- Manufacturing site safety and environmental practices: Informs effective control measures on manufacturing sites, including compliance with regulations.

- Downstream uses: Classification affects the suitability of a material's use in consumer and professional products, such as electrics and electronics, food packaging, and building materials.

Our priorities

Metals and minerals are integral to daily life, no matter where in the world. Rather than granting a licence to produce at any cost, this creates a responsibility to ensure that extraction, use, and disposal are sustainable, minimising harm to people and the environment.

-

International policy engagement on materials stewardship

The Materials Stewardship Facility (MSF) – jointly funded by ICMM and member associations – serves as a cross-commodity forum to support informed international policy engagement. Its aim is to build relationships and engage key stakeholders to foster a shared understanding of the principles and practices that ensure the sustainable use and supply of minerals and metals throughout their lifecycle.

- As part of our commitment to mercury risk management, ICMM has been an active contributor to the implementation of the Minamata Convention, providing technical expertise to support the developments of several Convention guidelines focused on the sound management of mercury – from effective pollution controls to mercury waste management. Notable contributions include: Guidance on Mercury Releases; and Guidance on Best Available Techniques and Best Environmental Practices (for air pollution).

- ICMM has also played a key role in the development of the Globally Harmonised System for the classification and labelling of chemicals (GHS). Working closely with governmental experts, we supported efforts to shape the environmental hazard assessment of metals and metals compounds to reflect the latest science.

-

Collaborative research to inform and support engagement on international materials stewardship policy developments

The Materials Stewardship Facility (MSF) – jointly funded by ICMM and member associations – aims to advance the principles and practices that ensure the sustainable use and supply of minerals and metals throughout their lifecycle. This includes supporting the development of scientific evidence to address knowledge gaps and inform science-based policies, legislation, and product selection principles.

- Recently published peer-reviewed research sponsored by ICMM and the MSF includes:

-

Santero, N., & Hendry, J. (2016). Harmonization of LCA methodologies for the metal and mining industry. International Journal of Life Cycle Assessment, 21(9), 1543–1553. https://doi.org/10.1007/s11367-015-1022-4

-

Owsianiak, M., van Oers, L., Drielsma, J., Laurent, A., & Hauschild, M.Z. (2022). Identification of dissipative emissions for improved assessment of metal resources in life cycle assessment. Journal of Industrial Ecology, 26, 406–420. https://doi.org/10.1111/JIEC.13209

- This methodology examines the use of dissipation rather than depletion to assess metals' impact on resource availability, better reflecting their recoverability and recyclability.

-

Berger, M. (2024). Dissipation-based life cycle impact assessment of mineral resource use – a review, case study, and implications for the product environmental footprint. International Journal of Life Cycle Assessment, 29, 1177–1189. https://doi.org/10.1007/s11367-024-02318-6

-

- Recently published peer-reviewed research sponsored by ICMM and the MSF includes:

Associated member commitments

Principle 08: Responsible Production

Facilitate and support the knowledge-base and systems for responsible design, use, re-use, recycling, and disposal of products containing metals and minerals.

Position Statement: Mercury Risk Management

Promoting the responsible management of mercury down the value chain.

Latest updates

Supporting the SDGs

With our strong focus on sustainable development there is great potential for ICMM to support the mining and metals industry in making an important and lasting contribution towards the UN’s global goals. We work with members and partners to catalyse lasting social and economic progress that supports an end to poverty, protects the planet and ensures prosperity for all.

-

SDG 3: Good health and wellbeing

Mine workers are often exposed to occupational health risks such as respiratory diseases, including silicosis, and communicable diseases like tuberculosis and HIV/AIDS. Working arrangements like fly-in/fly-out can also contribute to mental health challenges, substance abuse, and domestic violence. Communities near mining operations, especially in areas with limited healthcare, may face increased vulnerability to diseases and accidents caused by mining-related traffic or uncontrolled discharges into water sources. Addressing these challenges requires proactive health and safety measures.

-

SDG6: Clean water and sanitation

Water is critical for mining operations and employee well-being, but poor water management can harm access and quality for surrounding communities. Companies must adopt sound water stewardship practices to balance operational needs with community and environmental sustainability.

-

SDG12: Responsible consumption and production

Mining generates essential materials for modern life but also produces significant waste. Increasing recycling rates and transitioning to a circular economy for metals require collaboration across the value chain. By reclassifying waste as a resource (e.g., using sulphuric acid from emissions controls in other industries), mining can drive innovation and job creation.

-

SDG 17: Partnerships for the goals

Mining companies bring significant expertise to partnerships that address sustainable development challenges. Sharing these experiences can inspire further collaboration and demonstrate the potential for collective progress toward achieving the SDGs.

.jpg)