Health and Safety Critical Control Management: Good Practice Guide and Implementation Guidance

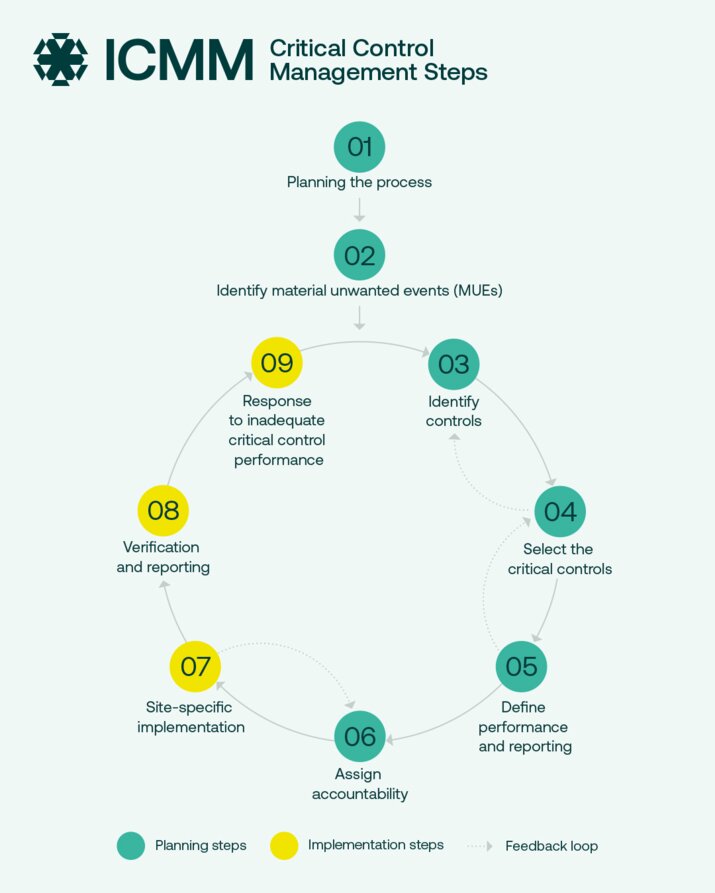

This document provides guidance on managing critical controls to prevent the most serious types of health and safety incidents, material unwanted events. Critical control management (CCM) is an integral part of risk management and aids in identifying the priority risks in a company and implementing critical controls to prevent an incident or mitigate its impact.

-

Most material unwanted events are associated with failures of known controls rather than because of failures to anticipate risk.

-

More can be less. Implemention of a smaller number of important controls can be a more effective way of preventing material unwanted events than an extensive hazard management plan with too many controls to practically implement and monitor. Simply put, some controls are more important than others.

-

A CCM approach provides:

- Clarity on which controls really matter (ie critical controls).

- Understanding of what these controls need to do to prevent an undesired event from happening.

- Decisions on what checks are needed to ensure that controls are working as intended.

- Accountability for the implementation of the controls (ie who is responsible for making it work?).

- Reporting on the performance of all critical controls.

- There is no one right way implementing critical control management. It needs to be tailored to suit individual companies and sites. What is important is having people with the right skills, experience and resources to implement it to a high standard.

Implementation guidance

While ICMM's Health and Safety Critical Control Management: Good practice guide outlines the core principles of critical control management, this companion document provides detailed implementation guidance.

It is designed to be used alongside the good practice guide, not in isolation, and it offers:

- Real-world illustrations using a fictional company, East Coast Coal (ECC).

- Visual bowtie diagrams showing how key risks—such as underground fires or diesel particulate overexposure—can be managed through critical controls.

- Practical tips for forming cross-functional teams or workshops to draw on the right expertise.